How Does Welding Work?

The welding industry gives us the chance to be part of building the modern world, while connecting us to a rich past that dates back to ancient history. By the end of this article, you will learn about the science and skill that our talented team of welders put into finishing each and every job for our clients. Perhaps it might even inspire your next custom metal fabrication or architectural steel project.

What is welding?

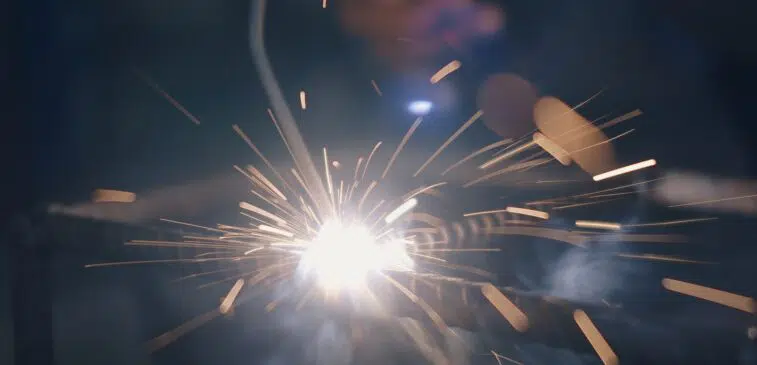

Welding is the fusing together of different kinds of metals with heat high and pressure to create complex structures. From larger projects such as shipbuilding to smaller projects like steel railings, the art of welding built the modern world you see around you today.

The history of welding work goes all the way back to ancient times when people were welding gold together to make circular boxes during the Bronze Age around 2,000 years ago. The Egyptians would follow that up by welding pieces of iron together 1,000 years later.

But welding became most popular and recognizable during the 1800s with the invention of arc welding and the discovery of acetylene. Thus, welding as we know it today was born.

What is the science behind welding?

There’s a lot of science in welding as it combines the fields of physics, chemistry, and mathematics and applies them in the metallurgical, mechanical, physical, electrical, and chemical sciences.

-

Gases

The most important gas in welding is oxygen, which is necessary for burning. Inert gases such as helium or argon serve as shielding gases that prevent contamination of the metal materials being bonded. These gases do not interact with the metals and other elements, therefore they are safe for welders to use. Acetylene gas is important in torch welding as a fuel source.

-

Carbon

Carbon is a substance that is essential to welding because it increases the strength and hardness of metals.

-

Metals

Welders work with many different types of metals depending on the projects they are working on. These metals include gold, copper, aluminum, iron, and nickel. Some projects require the combination of metals into alloys such as steel. Metals have different melting points, so some require higher temperatures than others to bond, up to 6,500F.

-

Currents

Arc welding employs direct current (DC) or alternative current (AC) as power sources to create an electric arc between a metal stick known as a rod and the metals being bonded together.

The rod, or electrode, is consumable or non-consumable. Consumable rods melt along with the base metals to work as a filler during the welding process, which strengthens the bond. Welders use non-consumable rods made of tungsten when a filler is not necessary.

Direct current is steadier than alternate current, which is why welders prefer the former over the latter in most projects.

How does the welding process work?

The two main welding processes today are arc welding and torch welding.

-

Arc Welding

Arc welding is highly skilled work that is used in a variety of applications from the construction of architecture and ships to the manufacturing of computers.

Using an electrode holder with an electrode rod, a welder turns on the power supply that will deliver either DC or AC through the holder. An electric arc between the electrode rod and the base metals begins to melt the metals into a melt pool. As the rod melts, a flux coating on the rod disintegrates, creating inert vapors of shielding gases to prevent contamination. The rod melts to combine with the other metals, strengthening the bond.

Types of arc welding include:

- Flux core arc welding

- Shielded metal arc welding

- Submerged arc welding

- Plasma arc welding

- Gas metal arc welding

- Gas tungsten arc welding

Arc welding work is the most common type of welding work process. But there is also torch welding.

-

Torch Welding

Using an oxyacetylene torch, a welder melts the metal materials and the welding rod by controlling them both simultaneously. Fuel combines with oxygen in the torch to create a flame out of the tip. The high heat melts metals and the rod, which is slowly fed into the flame with the other hand.

Torch welding not only melts metals but is also useful for cutting. While less popular than arc welding, torch welding work is common for maintenance and repair work along with more artistic ventures.

What does welding do to metal?

Welding melts metals in order to fuse pieces together at a joint. By exposing the metal to high heat, it weakens. But adding a filler material helps strengthen the bond by basically pulling on what you have just welded as it cools and shrinks.

Is welding work safe?

Welding has many safety procedures and equipment to prevent injuries. After all, welding produces sparks and slag that can do great damage.

- Heat resistant work gloves

- Helmet with eye protection

- Heat resistant welding jacket

- Fire-resistant welding pants with no cuff at the leg hole

- Respirator to prevent breathing in gases

- Ear protection

- Welding boots

As long as you gear up properly and weld responsibly, welding is generally safe.

Contact us for your welding work needs

Stronghold Welding has the equipment, training, experience, and skills to perform a variety of welding work. No project is too big or too small for our welders. We also offer quality repair work. If you break it, we can fix it.

Welding requires attention to detail and steady hands to do the best work possible. Whether we are fabricating metal railings or repairing the steel bucket of an excavator or fabricating auto parts, our professional welders get the job done right to meet your expectations. We can even come to you if you need welding done on your job site.

So if you need welding work, call us at 914-235-8280 or visit our website today! Stronghold Welding serves Westchester County, Dutchess County, Putnam County, and the New York Metropolitan area.