Types of Welding Gases

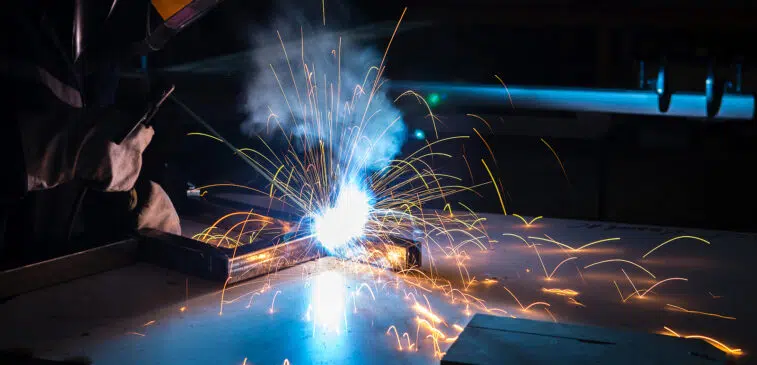

If you are just beginning to weld, it might be surprising to learn that there are several types of welding gases that welders use during the process. Welding is the process of fusing metal pieces together using high heat to melt the parts and allow them to cool.

As part of that process, welders employ several types of welding gases that work in different ways to get the job done. These gases are important for any aspiring or novice welder to learn about and understand.

What are welding gases?

Welding gases are a number of different gases that welders use or produce during the process of fusing metals together. One way in which a welder produces gas is by using an electrode that contains a flux. The electrode is basically a welding rod that contains filler materials that melt along with the metals a welder is trying to fuse together. This filler works to strengthen the joint.

Welders also use gases known as shielding gases to protect the weld area from oxygen, water vapor, and other contaminants. Gases are also necessary as a fuel source.

How many welding gases are there?

There are ten basic gases that welders use, and you can mix several of them together to create additional options. Learning what gases you can mix and how to mix them is an important, but also fun, part of the process.

What are the types of welding gases?

There are two main types of welding gases: inert gases and reactive gases.

- Inert gases are generally non-reactive under most conditions and include noble gases such as argon and helium.

- Reactive gases react with other elements in order to change welding conditions or the state of the weld.

It’s important to note that even inert gases can become reactive under the right conditions, which makes selecting the right gas for welding crucial. Safety should always come first.

What are the uses of gases in welding?

These gases have a few general uses that make them suitable for welding.

-

Shielding

Shielding gases are inert gases that displace air in the weld zone to prevent contamination by oxygen, nitrogen, and water vapor. Contamination of the weld can result in weakness.

-

Purging

Purging gases perform the same function as shielding gases, only on the reverse side of the weld zone. This is particularly useful while welding stainless steel.

-

Blanketing

Blanketing gases are not commonly in use but are sometimes necessary if you want to make sure your weld is free of contamination after the job is done. You can either place the item in a tank and fill it with the blanketing gas or drive gas out of the welding space and replace it with an inert gas.

-

Heating

Heating gases are useful while using a welding rod. A reactive gas passes through the welding gun to increase heat, which makes the filler react.

What are examples of welding gases?

-

Argon

One of the most common welding gases is argon, which is relatively cheap and inert under just about every condition except in extremely high temperatures. Argon is particularly useful as a shielding gas.

-

Carbon Dioxide

Carbon Dioxide, also known as CO2, is also useful as a shielding gas because it is inert, cheap, and easy to produce. However, it reduces weld quality, which is why welders usually mix it with another gas.

-

Oxygen

Oxygen is a reactive gas that is useful for shielding when mixed with other gases and as a heating gas to increase heat. It changes the fluidity of metal and can speed up the process.

-

Helium

Welders use helium either alone or with gases such as argon as a shielding gas or to boost heat, but it is expensive and hard to produce.

-

Nitrogen

Nitrogen is useful as a shielding and blanketing gas. It is also the most abundant gas and is inexpensive.

-

Hydrogen

Hydrogen is a reactive gas that is useful as a shielding gas but can generate high heating temperatures up to 7200° F to melt metals with high melting points.

-

Acetylene

Acetylene is a fuel source used to light acetylene torches to cut and weld metals at high temperatures.

-

Propane

Welders often use propane for brazing, a process of melting metals with fillers, after welding is complete.

-

Propylene

Propylene is a blend with oxygen that is suitable for fusion welding, heating, and brazing.

-

Compressed Air

This gas helps produce a stronger flame at a lower temperature. Welders usually mix it with another fuel.

What type of gas is used to weld steel?

Oxygen, in combination with acetylene, produces a flame hot enough to weld steel. It’s the only type of flame capable of this feat. Argon and carbon dioxide can weld mild steel.

What are mixed gases?

Sometimes welders mix gases to achieve changes in the way a metal melts or to change the atmosphere of the weld zone. Common mixes include argon and carbon dioxide to create a smooth weld, helium and argon to weld aluminum, or nitrogen and hydrogen for welding stainless steels. There are other combinations and argon is usually one of the gases.

What is the most common welding gas?

Since it is usually mixed with other gases to create combinations because it is inert, argon is one of the most common types of welding gases. Specific welding processes do use some gases more than others. But carbon dioxide is the most common because it can be used in its pure form or mixed with other gases. It’s also found in abundance.

How can I prevent exposure to welding gases?

Weld in an area with proper ventilation and wear protective gear such as a mask so you don’t suffocate. Inspect your gas tanks for possible leaks or weaknesses. Take regular breaks to reduce possible exposure.

Contact Stronghold Welding

Stronghold Welding has the expertise and skills to complete any welding project. We are knowledgeable in all the types of welding gases and how to use them properly and safely. We proudly serve Westchester County, Dutchess County, Putnam County, and the New York Metropolitan area. To contact us, call our office at 914-235-8280 or visit our website today!