What Is Arc Welding?

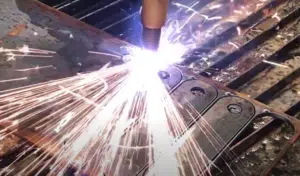

Arc welding is one of the most popular forms of welding in use today over a variety of applications that have been instrumental in building our modern world. Using an electric current, arc welding fuses two metals together by melting them at the joining point.

Although arc welding is common, it is particularly useful in the shipbuilding, automotive, and construction industries. In those industries, arc welding is crucial to quickly make strong connections that will last.

History of Arc Welding

The development of arc welding began in 1800 with the discovery of short electric arc pulses. This discovery, along with the development of continuous electric pulses in 1802, led to a presentation of arc welding at the 1881 International Exposition of Electricity in Paris.

From there, arc welding began taking off and different types of arc welding came about. But it is World War I where this method really came to the forefront through its application in shipbuilding. At a time when riveted steel plates were still the norm, the new method allowed for faster repairs and production.

After proving itself useful during wartime, the method would go on to develop even more over the next 40 years. The developments gave rise to several types of arc welding that continue to be in use today.

How Does Arc Welding Work?

The process involves the use of alternating current (AC) or direct current (DC) as a power supply to generate heat up to 6500°F in order to melt metals to fuse them. The arc moves manually or mechanically along the joining point. The current runs through an electrode cable that attaches to the power supply and an electrode holder or stinger. The stinger holds an electrode, which is basically a conductor rod the current runs through to weld pieces of metal together.

The electrode can be either consumable or non-consumable. If it is consumable, it will melt into the weld pool as a filler metal. In order to prevent metals from reacting to oxygen and nitrogen in the air, welders utilize a shielding gas or slag. Once the weld is complete, it must cool to create a permanent bond.

DC Current vs AC Current

Both currents have value in arc welding but have different uses depending on the job that needs to be done.

Alternating current is generally more volatile because the electrons are constantly changing directions. That’s why welders tend to make it their secondary choice when selecting a power supply for a project. However, AC can be useful in certain circumstances. For instance, using AC can prevent a blowout of the arc and is excellent for transmitting electricity over longer distances.

Direct current is more stable and smooth because the electrons flow in a single direction and has primary usage in projects that require lower voltage and in stick welding, which uses a consumable electrode. The steadiness and stability of direct current make it the preferable choice among welders.

Consumable and Non-Consumable

As we already know, a consumable electrode is a conductor rod that melts while in use. It not only conducts the current to melt two pieces of metal together, but it also provides a supply of filler metal as it melts. Selecting the right electrode is essential because the electrode metal must be chemically compatible with the joining metals.

A non-consumable electrode rod, such as a tungsten rod that requires a much higher temperature to melt, does not melt as it conducts the current. Because the electrode remains intact, there is no concern about compatibility with other metals.

Types of Arc Welding

There are two main classes of arc welding: consumable and non-consumable. But there are several kinds of arc welding types in each class.

Consumable

-

Metal Inert Gas (MIG) Welding

MIG welding utilizes an inert gas to shield the metal from contamination. An example of this would be using helium or argon when welding aluminum.

-

Metal Active Gas (MAG) Welding

Active gases such as a mixture of argon, carbon dioxide, and oxygen serve as a shield while welding steels. The composition of the gas affects the stability of the arc, metal transfer, and amount of spatter. It also regulates the behavior of the melt pool.

-

Shielded Metal Arc Welding (SMAW)

Also known as stick welding, the electrode has a flux coating, a chemical layer that acts as a purifying or flowing agent to protect the weld pool from contamination. A melt pool forms after applying a high enough heat.

-

Fluxed Core

Primarily used to weld thicker metals, FCAW requires a consumable electrode containing flux core and continuous voltage to create a constant arc length. It does not require a shielding gas, and the electrode is continuously fed by a wire feeder.

-

Submerged

The electrode and flux must melt to become conductive, creating a path for the current to flow from the electrode to the metal. The flux also blocks fumes and radiation.

-

Electro-Slag

This is a vertical process to weld thicker plates in one pass using an electric arc to melt the flux wire in the molten pool to create slag on top, which generates heat for additional melting.

-

Arc Stud

A quick welding method to join a nut or fastener.

Non-Consumable

-

Tungsten Inert Gas (TIG)

The electrode is made of tungsten to prevent it from melting during welding. Inert gases such as argon and helium provide shielding.

-

Plasma

Plasma arc welding again uses tungsten as an electrode. However, this method utilizes a plasma torch so the electric arc can create plasma that the torch pushed through a borehole to separate it from the shield gas. Water cools the plasma torch.

Contact Us

Arc welding is used in a variety of applications ranging from large projects such as shipbuilding, car manufacturing, and structural engineering to smaller projects such as HVAC units, computers, and tools. It’s a skill that is crucial in today’s world, and Stronghold Welding has a team of welders who can provide the arc welding services you need. Call us at 914-235-8280 or visit our website today! We serve Westchester County, Dutchess County, Putnam County, and the New York Metropolitan area. Large or small, you count on us to get the job done.